Product Reviews

Wednesday 03 April, 2024

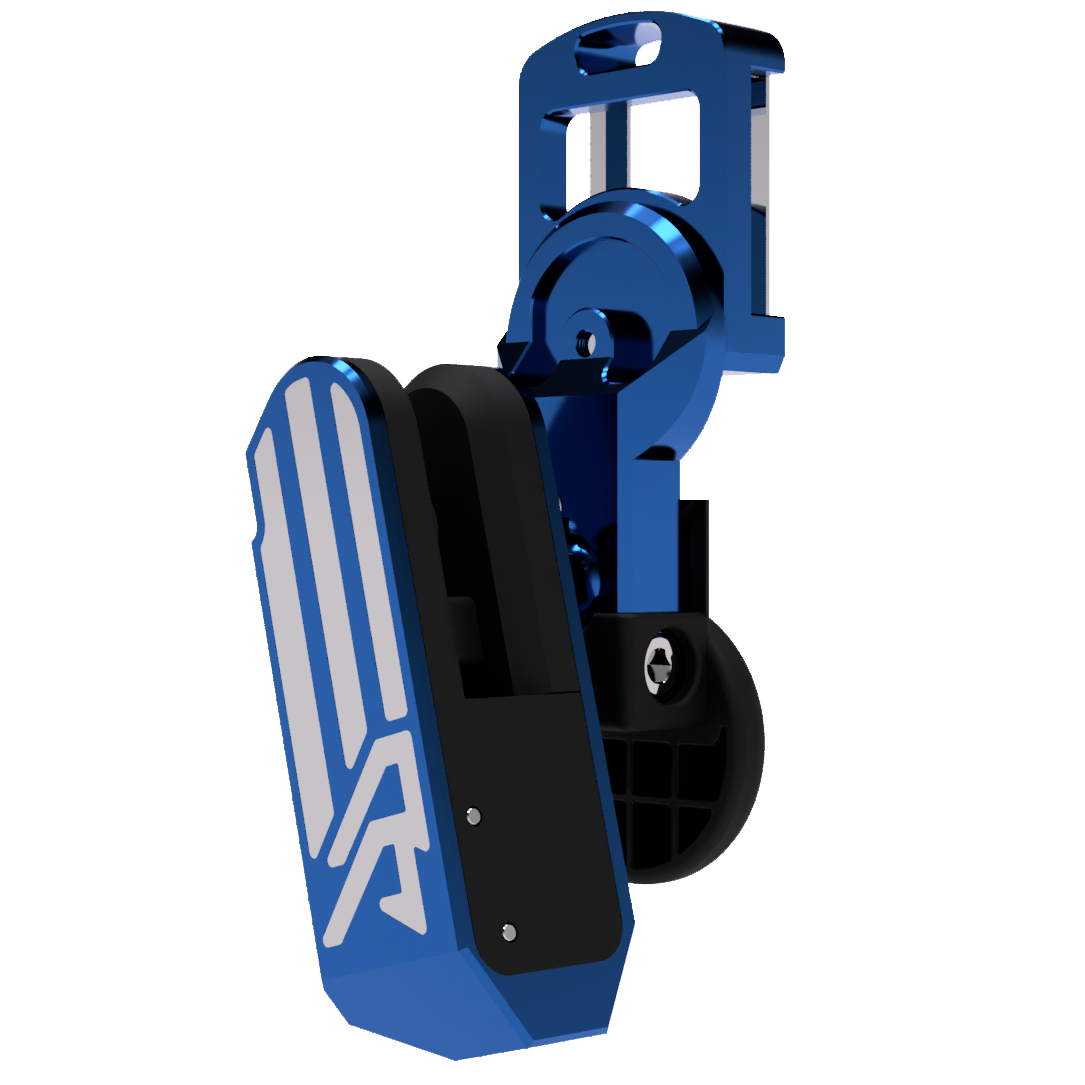

Works as intended. Like to get less hold when I just use it for storing the mag after clearing a stage

Tuesday 02 April, 2024

It is better than any other solution I have tried under $400! It just works...period.

(Bonus: Hornady primer tubes work with it too. No issues at all.)

Tuesday 02 April, 2024

The belt is a total game changer. It is very comfortable and doesn’t move around. Highly recommend this set up!

Monday 01 April, 2024

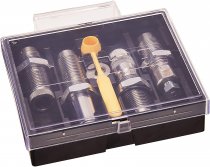

YES, I'm fairly new to progressive reloading. This is one of the slickest reloading items I have ever seen, and what a difference it made in the cases I load. I had never even heard of this before, I had no idea that the bulge didn't get taken care of with the sizing die! I recently started shooting IDPA, so I was going through a lot of rounds per month, being in CA this was becoming an issue for me. So, I started to reload my own with some success, but I was having issues with cases that wouldn't chamber correctly. This roll sizer fixed all of that with little effort, I feed it from my regular case feeder, and it will produce sized truly round cases very quickly.

Monday 01 April, 2024

A small accessory for a big help. Very handy. I recommend.

.webp)